WHAT ARE MOBILE BATCH PLANTS?

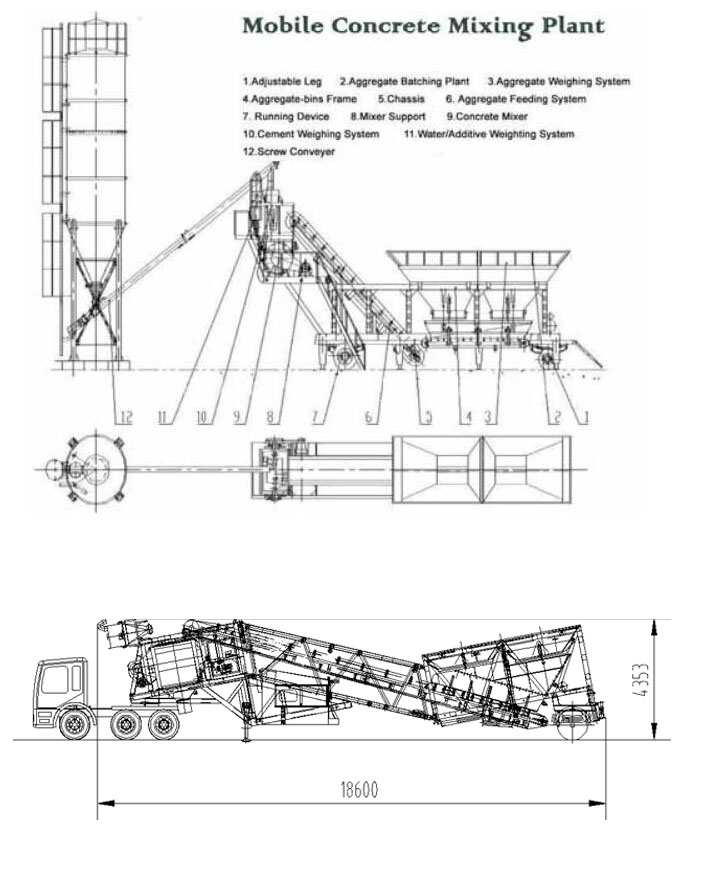

Mobile concrete batching plant is a transportable and easy-to-assemble plant used to manufacture batches of concrete mix time-savingly and efficiently. With all units fixed on one or two chassis, it can be towed by a truck tractor, implement faster and easier installation, disassembling, and translocating. The entire plant is pre-wired and plumbed for air and water, requires less concrete foundation, and sometimes no permission. It is especially suitable for the construction of small and medium-sized hydropower, highways, ports, airports, bridges, etc.

Portable concrete batching plant price varies from $52,700 to $300,000. The production capacity normally has a span from 25m³/h and 100m³/h, compared with that of stationary concrete factory widely from 25m³/h to 150m³/h. Basically you can say, the procurement cost of a mobile batch plant is mainly up to the production capability. As customization becomes a clear trend, the configurations specified by users increasingly profoundly influence the purchase costs.